| |

| |

|

Pars

Pipe :

Intelligent,

Rapid, Accurate, Easy to Use |

|

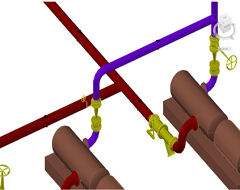

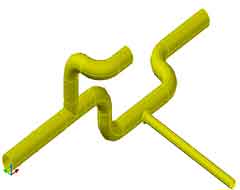

Pars Pipe is one of the Intelligent Pars Plant's

Modules. This Software focuses on Modeling and Creating of Pipes, Piping

Components, Fittings, Valves and Instruments.

Some Bold Features of

Pars Pipe can be pointed below :

- Pipe modeling in

three modes : Single Line, Double Line,

3D Model

- All Types of Connections such as :

Butt-Weld, Socket Weld, Threaded, Flange, PVC, GRP (Glass Reinforced Pipes)

and Sanitary

- Intelligent and Automatic

modeling of

all kind of Components and

Connections uses in Piping such as : Pipe,

Valve, Fitting ( Flanges, Elbows, Reducers, Tee, Tee Reducer, Cross, Cross

Reducer) Instruments, Vibration Joints, Expansion Joints, Filters

and etc. according to PMS.

- Automatic and Correct Selection and

Placement of Reducers on the

Change Size situations.

-

Automatic and Correct Selection and

Placement of Tee,

Reducers and Tee Reducers

on Connection point

of three Pipes with specific sizes.

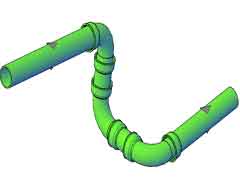

- Pipes Proper

Distance observed according to Pipe Ways

Space Standard.

- Easy and rapid

Stretch,

Movement and Replacement of Pipes, Components, Valves and etc.

-

Easy and rapid

Deletion

of Pipes, Components, Valves and etc.

- The Control

Process of Length , Direction, Slope, Elevation, Size, Type While

Piping is doing by the User.

- Automatic

Routing.

- Auto Clash

Process.

- The

Alignment Process in all Coordination Axis

- Automatic Usage

and Placement of Connections

- Automatic

connection of Two Piping Systems.

- The Process of

Moving Pipe Groups with Database and Coordination Management.

-

The Process of Copying Pipe

Groups with Database and Coordination Management.

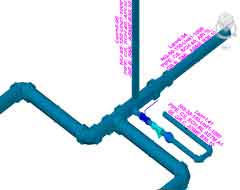

- Neighbor

Management of all Pipes and Components.

- The Automatic

and Manual Management of Line Numbers.

- The Process of

Automatic Creation of Bolts and Half Couplings.

- Instruments and

Valves Rotation.

- Automatic

Presentation of

Component's Data.

- Search

and Presentation according to Line Numbers.

- Data Writing

Process.

- MTO

Calculation and Estimation.

- Weight

Calculation.

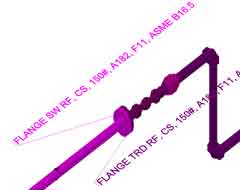

- Exportation to

Caesar II ( Stress Analyze Software).

- Isometric,

Orthography and Piping Plans.

- Line List,

Valve List, Equipment List, Tie - In Line to Equipment List, Tie - In Line

to Line List.

|

|

|

|

|

|

|

|

|

|

| |

|