| |

| |

|

Pars

Plant

4.0 :

A software Created for People

who believe

life is worth living

instead of working. |

|

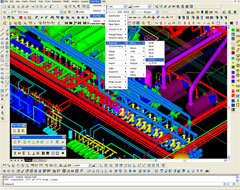

Parla Sanaye Co. Proudly notifies : Design, Create and

Utilization of Intelligent and Engineering Pars Plant (which has

extensive use in process of 3D modeling of Oil, Gas, Petrochemical and Power

Plants. and Creating projects As Built Plots) by collaborative effort

of more than 30 of scientific elite and engineers has been completed. Pars

Plant Software is Plug-In Software, which is on the AutoCAD environment and

has great deal of abilities which user can use. This software has a comprehensive data base including Valves, Connections,

Pumps, Vessels and other components and equipments which is used on Oil, Gas and

Petrochemical projects according to ANSI, ASTM, ASME, API, DIN, IPS and

IGS Standards.

Most Users believe that a designing software must be Rapid, Accurate

and most importantly Flexible in order to answer the user's needs in the

best way. Pars Plant considering these abilities is designed the way that

user can benefit its functions with high accuracy and velocity.

On the year 2008, more than 50 copies of Pars Plant (version 2.0 ) has given

to Iran's Oil Company which has been distributed in Organs below :

- National Iranian Oil Refining and Distribution Company

( NIOPDC)

- Gachsaran Oil & Gas

Production Company

- The Pars Special

Economic Energy zone

- Esfahan Oil Refinery

Company

- BandarAbbas Oil

Refining Company

- BandarEmam

Petrochemical Company

- Kharg Petrochemical

Company

- Tehran Province Gas

Company

- PetroPars Company

|

- Iranian Oil Pipeline

and Telecommunication Company

- Management Oversight of

the NIOC

- Central Oil Company

- Damash Oil Refining

Company

- South Pars Gas Complex

- Tabriz Oil Refining

Company

- South Zagros Oil & Gas

Production Co.

- West Zagros Oil & Gas

Production Co.

- East Zagros Oil & Gas

Production Co.

|

|

|

|

Some

Important Features of

Intelligent Pars Pars can be pointed below :

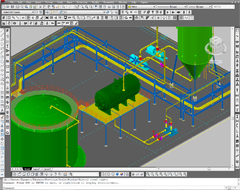

- Greatly Increase of Velocity, Accuracy and

Quality in Plant Designing.

- Accurate and Trustworthy 3D modeling

Presentation.

- Comprehensive DataBase ( according to

International Standards)

- High Information Process

- Minimize waste of raw materials.

- Project Simulation

- Optional link to MESC codes or International

Standard Definitions on MTO and Isometric reports.

- Including more than 900 Material Codes

- Create Piping Material Specification on minimum

Time possible

- Full complex of Reporting : Isometric, Orthography,

Piping Plan, MTO, DIA INCH ,Line List, Valve List, Equipment List and

etc.

- The Automatic Creation of Middle Links such as :

Flanges , Gaskets, Nipples, Unions, Eccentric Reducers, Concentric Reducers,

Bolts, StubEnds and etc.

- The Automatic Selection Process of Size and Material

according to Catalogue and Line Number.

- The Automatic Usage of Line Numbers.

- The Automatic Management of Flow direction

according to Pump's Suction and Discharge.

- Automatic Group Supporting (With or Without Insulation )

according to Pipe Ways Space Standard

- The Pars Plant Chan be used in Client Server

Network system, Using only one software lock and one file to work.

- The Pars Plant is a Flexible software, For Example

if there was some changes in Project Line Numbers, even after the

completion of the project, Users can Edit and modify the project easily and

with the Least time and cost possible.

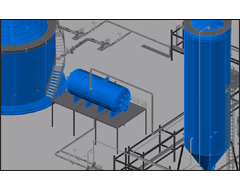

- Pars Plant gives the opportunity of designing 3D model of

Oil, Gas, Petrochemical, Power Plants and designing the As Built Projects

with Least Time and Cost Possible

- English Based Help

- User Friendly and Easy to Learn ( It can be

mastered in only 32 hours of training)

This Software contains a

comprehensive Database which can be pointed below:

- Variety of Pipes, Such as : Carbon Steel, Stainless

Steel, Alloy Steel, GRP, PVC and etc.

- Variety of Valves, Connections and

Components, Such as : Butt-Welded, Threaded, Socket-Welded, Flanged

and etc.

- Variety of Instruments

- Variety of Pumps

- Variety of Equipments, Vessels, Towers

and etc.

- Variety of Exchangers

- Variety of Steel and Concrete Structures

- Variety of Steel Profiles

- Variety of Connection for Structures

- Variety of Supporting according to Pipe Support

Standard

- All Components according to ANSI, ASTM, API, DIN, IPS,

IGS Standards

|

|

|

|

|

|

-

Windows

8 and Windows 8.1 Standard, Enterprise or Professional

Edition, Windows 7 Enterprise, Ultimate, Professional or

Home Premium Edition or Windows XP Professional or Home

edition (SP3 or Later) Operating System

-

For Windows 8, Windows 8.1 and Windows 7

: Inter Pentium 4 or AMD AthlonTM Dual-Core

processor, 3.0 GHz or higher with SSE2 technology

-

For Windows XP :

Pentium 4 or Athlon Dual-Core Processor, 1.6 GHz or

higher with SSE2 technology

-

2 GB RAM ( 4 GB

recommended)

-

1024 x 768 display

resolution with true color (1600 x 1050 recommended)

-

1280 x 1024 True

color video display adapter 128 MB or greater, Pixel

Shader 3.0 or greater, Microsoft Direct 3D-capable

workstation-class graphics card

-

1 GB hard disk

Space available not including the space required for

AutoCAD

|

|

Guaranty And Warranty

Services :

- Pars Plant will be trained by Pars Plant Training

Team, Duration of this Training is 32 Hours and at the End of

training Students will design a Pilot Plan. The Training Service will

be provided Free for One Year after the Sale Contract, and after that

Can be pointed in Warranty Contract.

- Pars Plant Bug Fix is an Online service which is

Free

- Software Upgrade ( Every three months) which Users can

Change their Current Version with the New Version of the software. This

service will be Free in case of Warranty Contract.

- User's Needs and Feedbacks will be designed

and created as Modules and Applications For them. This service

will be Free in case of Warranty Contract.

- Parla Sanaye Co. will help the Users on their Projects

for one year after the Sale Contract for Free and after that Can be

pointed in Warranty Contract.

|

|

Intelligent Pars Plant

Software is consisted of Different Modules : |

|

|

|

|

This is a 13 minutes

film, Which contains the modeling and designing a plot plan with PARS

PLANT software

|

|

| |

|